In recent years, industries have quickly changed with digital technology. One important idea from this change is digital twins. First used in aerospace, digital twins are now used in many fields like manufacturing, healthcare, smart cities, and farming. By July 2025, the global digital twin market is worth more than $25 billion and keeps growing as companies look for better efficiency, accuracy, and new ideas.

At its core, a digital twin is a real-time digital replica of a physical object, system, or process. It allows for simulation, monitoring, and analysis of physical entities using live data. By providing insights into operations and enabling predictive maintenance, digital twins are reshaping the way industries approach problem-solving, optimization, and innovation. Understanding this technology and its wide-ranging applications is crucial for anyone involved in engineering, business development, or digital innovation.

What Is a Digital Twin?

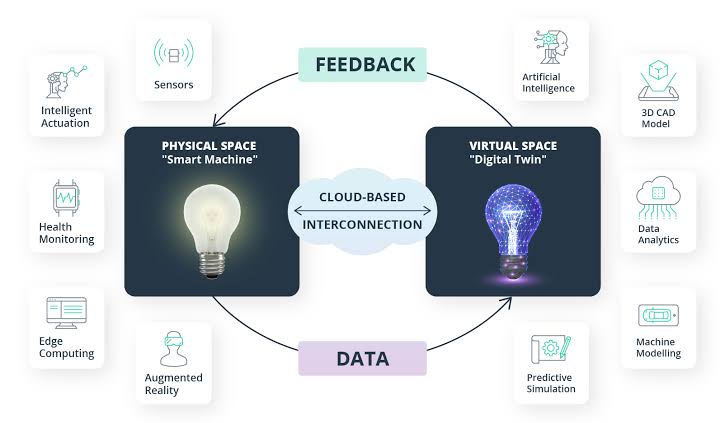

A digital twin is a virtual model that accurately reflects a physical asset, process, or system. It is created using real-time data collected through sensors, Internet of Things (IoT) devices, and advanced analytics. This data allows the virtual twin to mimic the behavior, performance, and condition of its real-world counterpart.

The concept goes beyond simple simulation. Digital twins are dynamic, meaning they are continuously updated with new information. This creates a feedback loop between the physical and digital worlds, where actions in one environment can influence the other. As of 2025, advances in cloud computing, AI, machine learning, and edge computing have made digital twins more powerful, accessible, and scalable than ever before.

Key Components of Digital Twins

Digital twins typically consist of four primary elements. The first is the physical entity, which could be a machine, vehicle, building, or even a human organ. The second is the digital replica, a software model that mirrors the characteristics and functions of the physical entity.

The third component is the connection layer, which includes sensors, IoT networks, and data communication systems that transmit real-time information from the physical world to the digital model. Lastly, the analytics and visualization tools interpret the data, offer insights, and predict outcomes. Together, these components enable continuous improvement, automation, and intelligent decision-making.

Applications in Manufacturing and Industry 4.0

Manufacturing is one of the earliest adopters of digital twin technology. In smart factories, digital twins are used to monitor production lines, predict equipment failures, and optimize resource allocation. By simulating different production scenarios, companies can identify inefficiencies, reduce downtime, and improve product quality.

As of July 2025, many leading manufacturers are using digital twins for entire factory operations. These virtual models allow managers to foresee potential disruptions and adjust schedules in real time. For instance, if a machine shows signs of stress, its digital twin can trigger maintenance before a breakdown occurs. This predictive maintenance approach saves millions in repair costs and productivity loss.

Digital Twins in Healthcare and Medicine

Digital twin technology has also made impressive strides in healthcare. In this sector, digital twins can represent organs, patient conditions, or entire hospital systems. By using data from wearable devices, electronic health records, and diagnostic tools, healthcare providers can create personalized digital models of individual patients.

This allows doctors to simulate treatment outcomes, optimize surgical procedures, and monitor chronic conditions with greater precision. In 2025, digital twins are being tested in cardiovascular care, diabetes management, and even mental health therapy. Hospitals are also using digital twins to manage resources, predict patient flow, and improve response times in emergencies.

Role in Urban Planning and Smart Cities

Cities around the world are embracing digital twins to design, monitor, and manage urban infrastructure. A digital twin of a city can include buildings, roads, utilities, public transportation, and even environmental conditions. Planners use this data to model traffic patterns, evaluate energy consumption, and prepare for disasters.

For example, if a flood is predicted, a city’s digital twin can simulate the impact on roads and neighborhoods, helping emergency services plan ahead. In 2025, cities like Singapore, Dubai, and Helsinki are pioneering this approach to create more livable, efficient, and resilient urban spaces. Digital twins also enable public participation by providing visual simulations that help residents understand development projects and offer feedback.

Enhancing Agriculture and Environmental Monitoring

Agriculture is another field benefiting from digital twin integration. Farmers and agricultural companies use digital twins to track crop health, soil conditions, weather patterns, and irrigation systems. These virtual models help in making real-time decisions about planting, fertilization, and harvesting, leading to increased yields and reduced waste.

With growing concerns over climate change and food security, digital twins are now part of larger sustainability strategies. They enable better forecasting, reduce the need for chemical inputs, and promote precision agriculture. In 2025, many agritech startups are offering digital twin solutions tailored to small and medium-sized farms, making the technology more inclusive and impactful.

Digital Twins in Aerospace and Automotive

The aerospace industry was among the first to deploy digital twins for high-value equipment like jet engines and spacecraft components. Engineers use digital twins to simulate stress, wear, and failure rates under various conditions. This reduces testing time, lowers risk, and improves safety.

In the automotive sector, digital twins are used to design and test vehicles virtually before physical prototypes are built. As of July 2025, electric vehicle manufacturers are integrating digital twins into their production and maintenance systems. They allow for real-time monitoring of battery performance, energy efficiency, and overall vehicle health, contributing to longer life cycles and better customer satisfaction.

Challenges and Future Outlook

Despite their many advantages, digital twins come with challenges. High initial costs, data security concerns, and the complexity of integration can hinder adoption, especially for smaller organizations. Ensuring data accuracy and managing the vast amount of information generated also require advanced infrastructure and skilled personnel.

However, as technology matures and becomes more affordable, these barriers are gradually being overcome. Edge computing, 5G networks, and AI-driven data analytics are making real-time synchronization more reliable and cost-effective. Looking ahead, digital twins are expected to play a major role in the development of the metaverse, autonomous systems, and advanced robotics.

Final Thoughts

Digital twins represent a major leap forward in how we understand, manage, and interact with the physical world. As of July 2025, their applications span multiple industries and continue to grow, driving innovation and efficiency across the board. By creating a virtual bridge to reality, digital twins empower organizations to simulate possibilities, predict outcomes, and optimize performance like never before.

Whether in healthcare, agriculture, manufacturing, or city planning, the impact of digital twins is profound and far-reaching. For professionals, businesses, and governments alike, embracing this technology could be the key to staying competitive and responsive in an increasingly complex world. As adoption increases and capabilities expand, the future of digital twins looks not only promising but transformative.