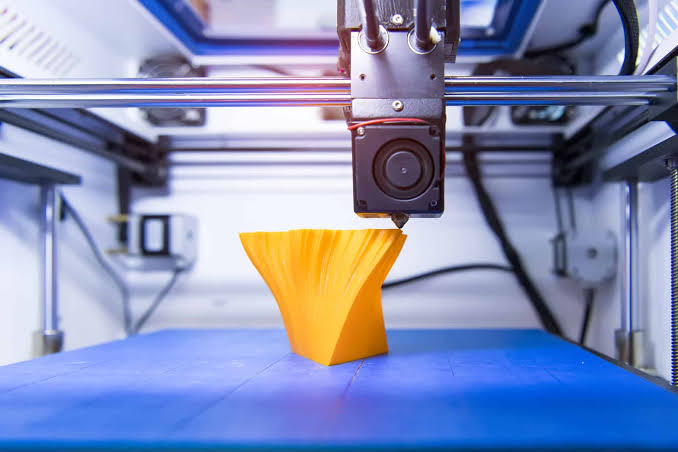

3D printing technology, also known as additive manufacturing, has advanced far beyond its early experimental stages to become a transformative tool across multiple industries. By 2025, 3D printing is no longer limited to prototyping but is being used for full-scale production, medical innovations, construction, and even food preparation. Its ability to create complex designs with precision and efficiency has redefined traditional manufacturing processes and introduced new opportunities for customization and sustainability.

The future of 3D printing holds immense potential as technology continues to evolve. With the integration of advanced materials, artificial intelligence, and faster printing techniques, 3D printing is expected to play a critical role in shaping industries ranging from healthcare to aerospace.

Evolution of 3D Printing Technology

Initially, 3D printing was primarily used for creating prototypes and small-scale models. Early printers were limited by slow printing speeds, low-quality output, and the range of materials available. However, ongoing research and innovation have led to high-speed, high-precision printers capable of producing durable, functional components.

Modern 3D printing incorporates multi-material and metal printing, enabling the creation of parts with complex mechanical properties. The cost of 3D printers has also dropped, making the technology more accessible to businesses and individuals.

Applications in Healthcare and Medicine

The medical field has been one of the biggest beneficiaries of 3D printing. Custom prosthetics, dental implants, and orthopedic devices are now produced with precision to meet the specific needs of patients. By 2025, advancements in bioprinting have enabled researchers to create functional tissues and organs, potentially revolutionizing organ transplants in the future.

Pharmaceutical companies are also experimenting with 3D-printed drugs, allowing for personalized medicine tailored to individual dosage requirements. This technology has the potential to improve treatment outcomes and reduce the cost of healthcare.

Aerospace and Automotive Innovations

3D printing is increasingly being used to manufacture lightweight, high-performance components for the aerospace and automotive industries. Companies such as Boeing, Airbus, and Tesla are using 3D printing to reduce production costs, minimize waste, and enhance fuel efficiency through lightweight designs.

The ability to produce complex parts on demand also reduces reliance on large inventories, improving supply chain efficiency. As 3D printing technology evolves, it is likely to become a standard tool in the manufacturing of vehicles and aircraft.

Construction and Architecture

The construction industry is embracing 3D printing for building homes and infrastructure at reduced costs and with greater speed. Large-scale 3D printers can create entire houses in a matter of days using sustainable materials like recycled concrete and composites.

By 2025, 3D-printed buildings are becoming more common, particularly in regions facing housing shortages. This approach not only reduces labor costs but also minimizes material waste, making it an environmentally friendly alternative to traditional construction methods.

Consumer Products and Customization

The future of consumer products is being shaped by 3D printing’s ability to offer personalized solutions. From customized footwear and eyewear to home décor and electronics, 3D printing allows consumers to design products tailored to their preferences.

E-commerce platforms are beginning to integrate 3D printing, offering customers the ability to order custom-made items that are produced on demand. This trend is set to revolutionize how consumers interact with brands and products.

Sustainability and Waste Reduction

One of the most promising aspects of 3D printing is its contribution to sustainability. Traditional manufacturing often involves cutting or shaping materials, resulting in significant waste. 3D printing, however, builds products layer by layer, using only the necessary material.

Recyclable and bio-based printing materials are being developed, further reducing the environmental footprint of manufacturing. As industries adopt greener practices, 3D printing is expected to play a major role in achieving sustainability goals.

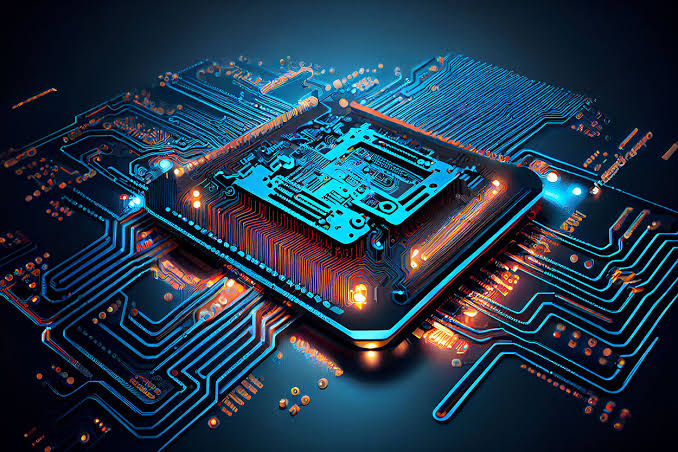

Integration with Artificial Intelligence

Artificial intelligence (AI) is set to enhance 3D printing by improving design optimization and predictive maintenance. AI-powered software can analyze data and suggest improvements to designs, resulting in stronger and more efficient printed parts.

Additionally, AI can help automate quality control by detecting flaws during the printing process, reducing errors and increasing production speed. The combination of AI and 3D printing is poised to unlock new levels of innovation across industries.

Future Possibilities of 3D Printing

Looking beyond 2025, 3D printing may extend to fields such as space exploration and food technology. NASA and other organizations are already experimenting with 3D-printed habitats for use on Mars or the Moon. Similarly, the food industry is exploring the use of 3D printing to create personalized meals using natural ingredients.

The potential for on-demand manufacturing of everything from spare parts to everyday goods suggests that 3D printing will continue to disrupt traditional supply chains and reshape the global economy.

Conclusion

The future of 3D printing technology applications is vast and full of potential. With its ability to enhance efficiency, enable customization, and promote sustainability, 3D printing is revolutionizing industries worldwide. By 2025 and beyond, its integration with AI, advanced materials, and innovative applications will continue to drive its growth and influence.

As this technology evolves, it will not only redefine manufacturing but also change how we live, work, and consume products, ushering in a future where customization, speed, and innovation are the norm.

Artificial intelligence is enhancing 3D printing by optimizing designs, automating quality control, and enabling predictive maintenance, which leads to stronger, more efficient parts and faster production.

Fascinating